- Capacity Range: 200 to 4,000+ tons, 60/50 Hz

- Low Pressure Refrigerant: R-514A and R-1233zd

- Compressor type: Centrifugal

- Direct drive, multi-stage compressor offers a more reliable design with a wider operating map and a flash economizer for enhanced efficiency and stability

- Validation of performance through myTest™ certification can provide base unit data founded on customer-defined parameters which replicate the jobsite conditions

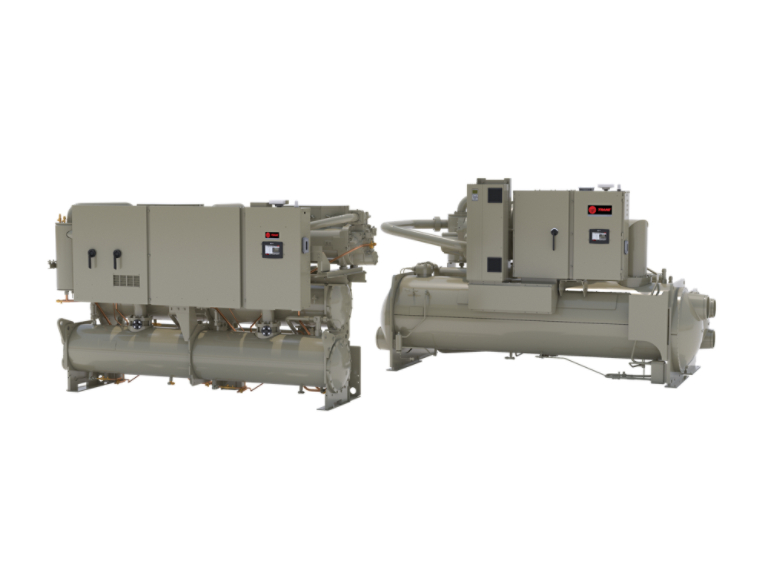

CenTraVac® Water-Cooled Centrifugal Chillers

Models CVHE, CVHF, CVHH, CDHF, CDHH

Overview

Efficient, sustainable and cost-effective thermal management.

Trane CenTraVac centrifugal chillers deliver high-capacity, energy-efficient thermal management for a variety of application challenges. Advanced chiller features help reduce operational costs and environmental impact.

- Capacity Range: 200-4000+ tons; 5,100-60,000 MBH

- Refrigerant: R-514A and R-1233zd

- Compressor Type: Centrifugal

- Low Pressure

- Controller: Symbio® 800-Unit Controller

-

Industry-Renowned Reliability

Trane CenTraVac centrifugal chillers feature a time-tested and proven low-pressure design utilizing environmentally friendly refrigerants R-514A and R-1233zd. They offer the benefits of low pressure with continued product enhancements in a leak-tight design. CenTraVac chillers provide 200 to 4,000+ tons of cooling with low and medium voltage power inputs. Options for solid-state starters and VFDs are available for improved energy use and precise temperature control.

-

System Enhancement Features

CenTraVac centrifugal chillers offer system enhancements features like integrated heat recovery, free cooling, and thermal energy storage for flexible operation to help manage peak demand. These options can help reduce water, heating, and power consumption, lowering operating costs. Enhanced flow management improves variable water-flow response. Some available options can provide 34-36°F leaving evaporator water without glycol, enhancing performance for specific applications.

-

Quiet and Efficient Operation

The CenTraVac compressor has only one moving part supported by two bearings, providing reliability through simplicity of design. The low-speed direct-drive design delivers highly reliable and efficient operation, while also reducing sound and vibration levels. Trane CenTraVac centrifugal chillers can operate with wider condenser delta Ts, leading to overall plant efficiency improvements. CenTraVac chillers can also unload at high lift conditions with a starter or drive due to their multi-stage compressor design, providing flexibility and efficiency in various operating conditions.

Product Information

-

CVHE

200 – 500 ton capacity

- 3-stage compressor

- Heating and cooling capable

- Free cooling option

- Symbio® 800 equipment controller

- R-514A refrigerant

-

CVHF

325 – 1,800 ton capacity

- 2-stage compressor

- Heating and cooling capable

- Free cooling option

- Symbio® 800 equipment controller

- R-514A refrigerant

-

CVHH

850 – 2,000 ton capacity

- Multi-stage compressor

- Heating and cooling capable

- Free cooling option

- Symbio® 800 equipment controller

- R-1233zd refrigerant

-

CDHF

1,450 – 3,950 ton capacity

- Multi-stage, dual compressor

- Symbio® 800 equipment controller

- R-514A refrigerant

-

CDHH

1,800 – 4,000+ ton capacity

- Multi-stage, dual compressor

- Heating and cooling capable

- Symbio® 800 controller

- R-1233zd refrigerant

CenTraVac® Water-Cooled Centrifugal Chiller

Since 1938, Trane has been engineering CenTraVac® water-cooled centrifugal chillers to meet your toughest demands. These chillers deliver high-performance, energy-efficient thermal management for a variety of application challenges, with advanced features that help reduce operational costs and environmental impact. In today's fast-paced world, reliability and trust are paramount. CenTraVac® chillers are engineered to provide consistent, dependable performance. Whether you need to maintain a comfortable environment or manage precise temperatures for critical processes, CenTraVac® delivers peace of mind with its award-winning technology. Our commitment to sustainability is reflected in every CenTraVac® chiller. By incorporating cutting-edge features and real-time performance monitoring, we help you focus on what truly matters: your people and your mission. Every building has a purpose, and we understand that your success depends on a foundation of trust. For those moments when every second counts, every degree matters, every innovation drives progress, and every lesson helps shape the next generation - choose CenTraVac. Trane designed. Trane backed. Industry trusted

Product Literature

Brochures

-

CenTraVac® Water-Cooled Centrifugal Chillers

CTV-SLB036-EN

-

CenTraVac® chillers CVHH & CDHH with Next-Generation Refrigerant, R-1233zd

CTV-SLB056-EN

-

Adaptive Frequency Drive Remote-Mounted for chillers CenTraVac Models CVHE and CVHF 460/480V and 575/600V 60 Hz applications

CTV-SLB031-EN

-

Adaptive Frequency Drive Compact unit-mounted drive - CenTraVac chiller models CVHE/CVHF 460/480V and 575/600V 60 Hz applications

CTV-SLB054-EN

-

Environmental Product Declaration - Trane Centrifugal Chillers

CTV-SLB070-EN

Installation Operation Maintenance (IOMs)

-

CenTraVac™ CVHH Chillers with Symbio™ Controls

CVHH-SVX003-EN

-

CenTraVac™ CDHF and CDHG Chillers with Symbio™ Controls

CDHF-SVX004-EN

-

CenTraVac™ CVHE, CVHF, and CVHG Chillers with Symbio™ Controls

CVHE-SVX005-EN

-

AFD with AdaptiView™ or Symbio™ - AFDL, VFDA

AFDL-SVU001-EN

-

Liquid-Cooled AFD - AFDE

AFDE-SVU02-EN

-

Remote-Mounted Medium Voltage Air-Cooled AFD - AFDJ

AFDJ-SVU01-EN

-

Remote-Mounted Medium Voltage Air-Cooled AFD - VFDB

VFDB-SVX001-EN

Software & Firmware

FAQs

Your water-cooled chiller questions, answered.

A water-cooled centrifugal chiller is used for the thermal management of large buildings, data centers, or industrial processes. Centrifugal chillers utilize centrifugal force to compress refrigerant and transfer heat from the building or process to a water loop, which is then cooled by a cooling tower or other heat rejection device. These chillers are known for their high efficiency and ability to handle large cooling loads.

Yes! In fact, for data centers with mission-critical cooling needs, the CenTraVac® Duplex® model CDHH extends the reliable CenTraVac design to deliver over 21MW of cooling capacity for Data Center customers. Simplex and Duplex chiller designs provide a wide range of chiller capacities, all with higher evaporator water operation compared to a standard chiller. CenTraVac® designs enable Data Centers to meet required cooling needs while still enhancing the efficiency of their plant operation for applications requiring cooling towers, dry coolers, or heat recovery opportunities. CenTraVac® chillers are available in multiple voltage options from 460V all the way up to 12kV with various starter and drive options for configurability.

A water-cooled centrifugal chiller operates through a series of steps:

- Evaporation: The refrigerant absorbs heat from the building or process in the evaporator, causing it to evaporate and turn into a vapor.

- Compression: The gaseous refrigerant is then compressed by a centrifugal compressor, increasing its pressure and temperature. Centrifugal compressors use a rotating impeller to impart kinetic energy to the refrigerant, increasing its pressure and temperature. This type of compressor is known for its efficiency and ability to handle high cooling loads, making it ideal for large-scale applications.

- Condensation: The high-pressure, high-temperature refrigerant gas flows into the condenser, where it releases its heat to the cooling water circulating through the condenser tubes. This causes the refrigerant to condense back into a liquid.

- Expansion: The liquid refrigerant then passes through an expansion valve, reducing its pressure and temperature before returning to the evaporator to repeat the cycle.

The Trane CenTraVac centrifugal chiller helps improve efficiency through several innovative features:

- Advanced Compressor Technology: The CenTraVac chiller uses a direct-drive, low-speed, multi-stage centrifugal compressor that reduces energy loss and helps improve efficiency.

- Heat Exchangers: The chiller's evaporator and condenser are designed to enhance heat transfer, reducing the amount of energy required to achieve the desired cooling effect.

- Environmentally Friendly Refrigerants: Trane's CenTraVac chillers use low-global-warming-potential refrigerants, which not only help improve environmental sustainability but also enhance system performance.

- Intelligent Controls: The CenTraVac chiller is equipped with our Symbio® 800 equipment controller that helps monitor and adjust operation in real-time, delivering enhanced efficiency and reliability.

These features help contribute to lower energy consumption, reduced operating costs, and a smaller environmental footprint, making the Trane CenTraVac centrifugal chiller a highly efficient and sustainable thermal management solution.

Looking for parts?

Customer Stories

Learn how we’ve helped customers like you.

-

King's Daughters Medical Center

King’s Daughters Medical Center upgraded its chiller system, maintaining OR temperatures at 62-66°F and humidity at 50-60%, meeting CMS standards and reducing complaints. -

Bon Secours Bellefonte Pavilion

Our Lady of Bellefonte Hospital upgraded its HVAC system with Trane, improving comfort and efficiency, reducing energy costs by $10,000/month, and enhancing rental space marketability. -

Willis-Knighton Medical Center

Willis-Knighton Medical Center upgraded its chiller plant with Trane, adding capacity, redundancy, and efficiency. The new system improved comfort, humidity control, and energy costs. -

Indorama chose Trane's solution with four 1250-ton CenTraVac™ chillers and a Tracer system, boosting cooling capacity and efficiency for their expansion.

-

Agnico Eagle's Laronde mine faced chiller failures. Trane custom-designed five 1300-ton CenTraVac chillers, improving safety, efficiency, and reliability for workers.

Agnico Eagle's Laronde mine faced chiller failures. Trane custom-designed five 1300-ton CenTraVac chillers, improving safety, efficiency, and reliability for workers.

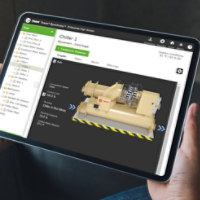

Services & Solutions

-

Tracer® SC+ Building Automation System

Tracer SC+ provides powerful building automation, enhancing control over comfort and efficiency. It supports Trane and non-Trane equipment, ensuring seamless integration and improved performance. -

Tracer Synchrony BAS software brings Tracer SC+ to life with a modern, intuitive interface, simplifying command over building systems into a few easy clicks.

-

Air-Fi® Wireless Communications

Easy, reliable, and secure networking for Trane® HVAC technology, enabling wireless communication between HVAC systems and building controllers. -

The Pivot Smart Thermostat system by Trane offers touchscreen control and mobile app access, simplifying energy management and building comfort for light commercial applications.